Application of galvanometer in laser cleaning

2024-12-19

Application of vibrating mirrors in laser cleaning

I. Introduction

With the rapid development of science and technology, laser technology has been widely used in various fields. Among them, laser cleaning technology has been widely used in manufacturing, cultural relics protection, medical equipment and other fields by virtue of its high efficiency, precision and environmental protection. As an important part of the laser cleaning system, the performance of the galvanometer directly affects the effect of laser cleaning.

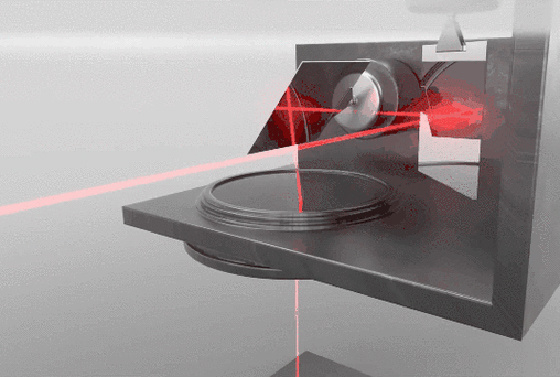

Overview of galvanometer

The galvanometer is an optical component that can precisely control the scanning and positioning of the laser beam. In the laser cleaning process, the vibrating mirror through high-speed vibration, so that the laser beam on the surface of the object for efficient, high-quality cleaning.

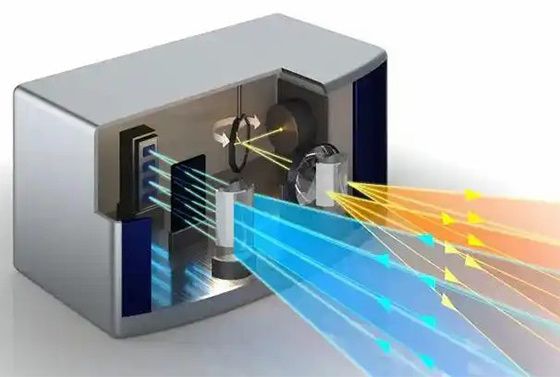

Three, laser cleaning vibration mirror application

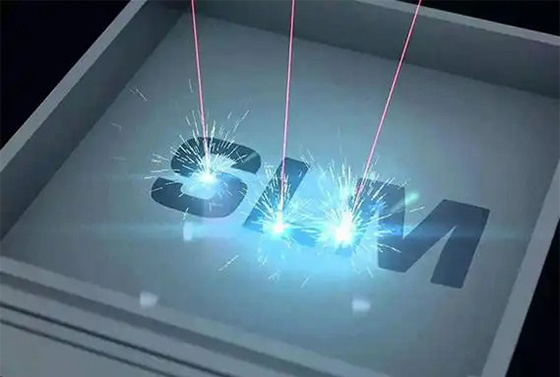

1. High-efficiency cleaning: vibrating mirror can accurately control the trajectory of the laser beam, so that the laser energy on the surface of the object to form a specific cleaning mode, such as point scanning, line scanning, etc., so as to achieve high efficiency and uniformity of the cleaning.

2. fine cleaning: for fine parts or cultural relics and other items that need to be handled carefully, the galvanometer can achieve high-precision positioning of the laser beam to avoid damage to the items.

3. Multi-material cleaning: the precise control of the galvanometer makes the laser cleaning adaptable to the surface cleaning of a variety of materials, such as metals, plastics, ceramics, etc. 4.

4. High degree of automation: the combination of galvanometer and computer control system can realize the automatic operation of laser cleaning and improve the production efficiency.

Fourth, the advantages of analysis

1. high flexibility: the vibrating mirror can realize the precise control of the laser beam and adapt to various cleaning needs.

2. good cleaning effect: through precise control of laser energy and cleaning mode, realize efficient and high quality cleaning effect.

3. Wide range of application: applicable to a variety of materials and fields of cleaning needs.

V. Conclusion

The application of vibrating mirror in laser cleaning has a wide range of prospects and importance. Through precise control of the laser beam trajectory and energy distribution, the vibrating microscope can realize efficient, high-quality cleaning effect, and adapt to a variety of materials and fields of cleaning needs. With the continuous progress of technology, the application of vibrating mirrors in laser cleaning will be more extensive, providing strong support for clean production and development in various fields.

Related News