Maintenance and Precautions for Vibrating Mirror Lenses

2024-12-19

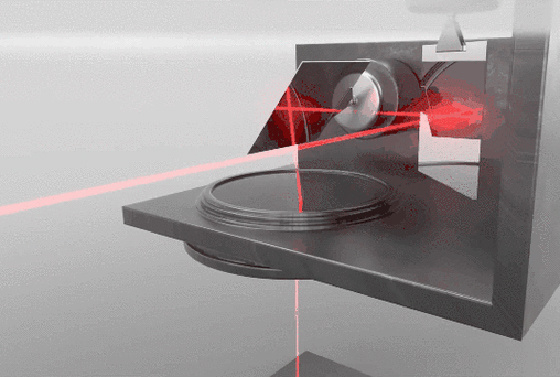

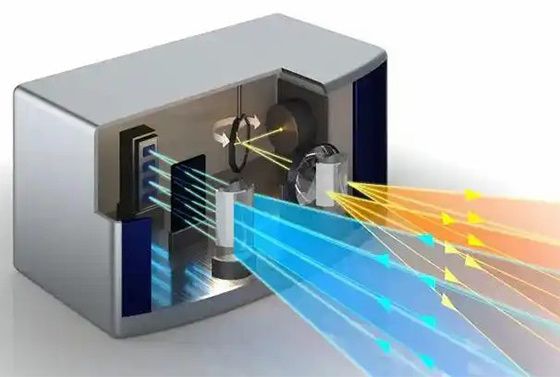

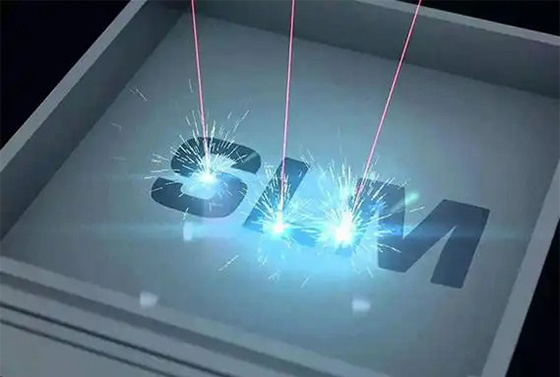

Vibrator lenses are an important optical component, widely used in laser processing, microelectronics industry, medical and other fields. In order to ensure the performance and service life of the galvanometer lens, the correct maintenance methods and precautions are crucial.

I. Maintenance methods

1. Cleaning: Regular cleaning of the galvanometer lens is the key to maintaining its performance. Use special cleaning paper or dust-free cloth with appropriate cleaning solution (such as alcohol or special cleaning solution) for wiping. Avoid the use of cleaning agents containing chemical compounds, so as not to cause damage to the lens.

2. Storage: When the galvanometer lens is not in use, it should be stored in a dry, dust-free environment. Avoid direct contact with dust, dirt and other contaminants that may affect the optical performance of the lens.

3. Regular Inspection: Regularly inspect the surface condition of the galvanometer lens, if scratches, stains or other damage are found, they should be dealt with in time. For minor scratches, you can use a special polish to repair; for serious damage, it is recommended to replace the new lens.

4. Professional maintenance: If the vibration mirror lens is malfunctioned or damaged, do not disassemble or repair it by yourself, but contact professional maintenance personnel for maintenance.

Precautions

1. Avoid impact: the vibrating lens is very precise, should avoid any kind of impact and extrusion to prevent the lens from cracking or damage.

2. prevent pollution: avoid using chemicals, grease, sweat and other pollutants in contact with the lens, so as not to cause damage to the lens.

3. Reasonable use: When using the galvanometer lens, should follow the operating procedures to avoid over-adjustment or improper use of the lens damage.

4. Temperature and humidity control: vibrating lens is sensitive to temperature and humidity, should avoid storing in high temperature and high humidity environment, so as not to affect its performance.

5. Correct installation: When installing and dismantling the galvanometer lens, avoid contacting the lens with hard objects to avoid scratching or damaging the lens.

6. Professional operation: For complex maintenance and repair work, it is recommended to be operated by professionals to ensure the safety and performance of the lenses.

In conclusion, proper maintenance and precautions can ensure the performance and service life of vibrating mirror lenses. Through regular cleaning, reasonable storage, regular inspection and professional maintenance, the galvanometer lens can be effectively protected and its working efficiency and reliability can be improved. Meanwhile, following the precautions to avoid impact, pollution, reasonable use, temperature and humidity control and professional operation can ensure the safety and performance of the vibrating lens.

Related News