Laser Cutting

Scan Heads for Laser Cutting

Our high-performance scan heads are designed to enhance laser cutting operations by providing precision, speed, and efficiency. Ideal for a wide range of materials, our scan heads ensure clean cuts with minimal heat distortion, making them a perfect solution for industries ranging from automotive to electronics.

Key Features of Our Scan Heads for Laser Cutting

1. Precision Cutting

Achieve clean, precise cuts with high accuracy, ensuring minimal kerf width and sharp edges. Our scan heads allow for fine control of the laser beam, ensuring that even the most intricate cutting patterns are executed with precision.

2. High-Speed Performance

Our scan heads are optimized for high-speed cutting, allowing for faster processing times without compromising quality. Whether you’re cutting thin sheets or complex shapes, you can rely on our scan heads to improve your throughput and productivity.

3. Versatile Material Processing

Designed to handle a broad spectrum of materials—including metals (stainless steel, aluminum), plastics, ceramics, and composites—our scan heads deliver superior performance across a variety of cutting applications. This versatility makes them suitable for industries such as automotive, aerospace, electronics, and signage.

4. Reduced Heat-Affected Zone (HAZ)

The advanced technology of our scan heads minimizes the heat-affected zone, reducing warping and material deformation. This ensures that your cuts maintain both structural integrity and high quality, even when working with heat-sensitive materials.

5. Efficient Beam Control

Our scan heads use advanced galvanometer technology for highly efficient beam control. This allows for fine adjustments to focus, speed, and position, resulting in high-quality cuts with minimal energy consumption.

6. Long-Term Durability

Built to withstand continuous, high-demand operations, our scan heads are designed for long-lasting performance with minimal maintenance. With robust construction and reliable components, they are perfect for industrial environments that require durability and uptime.

Applications of Laser Cutting with Scan Heads

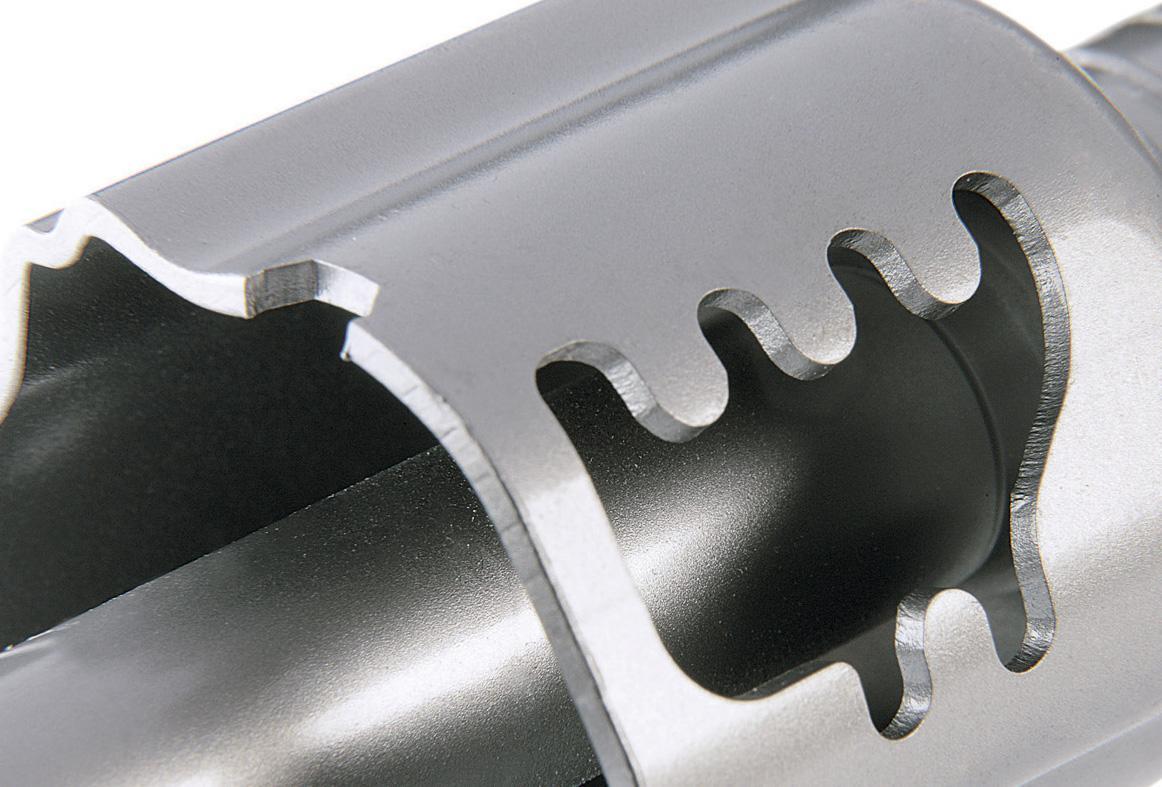

Metal Cutting: Precision cuts in sheet metal, pipes, and structural components.

Automotive: Cutting components like body panels, exhaust parts, and intricate designs.

Aerospace: Cutting aircraft parts, turbine blades, and other high-performance components.

Electronics: Cutting PCBs, flexible circuits, and battery components.

Signage and Decorative Materials: Cutting complex designs in acrylic, wood, and other materials for signage and art.

Why Choose Our Scan Heads for Laser Cutting?

High Precision: Achieve fine, accurate cuts with minimal thermal distortion.

Speed and Efficiency: Improve throughput with faster cutting speeds.

Material Flexibility: Work with a wide variety of materials, from metals to plastics.

Durability: Built to perform in demanding environments with minimal maintenance.

Seamless Integration: Easy to integrate with your existing laser cutting systems for enhanced performance.

About Tenfotai

Company since its inceptionhas introduced the domestic and foreign advanced professional technology, developed aseries with independent intellectual property rights of a new generation of laser scanning system, small and medium-sized poweroptical fiber cuttingfiber welding head, at present has been widely used in laser engraving, laser cutting, laserhe80,thesuch as Co2(in 10600)welding,optical scanningand other fields.

Contact

2nd Floor, Building A, Zhongli Sunshine Technology Park, No. 5 Jinlong 2nd Road, Baolong Community, Baolong Street, Longgang District, Shenzhen