Laser Sharpener in 3D Printing

2024-12-19

Application of laser galvanometer in 3D printing

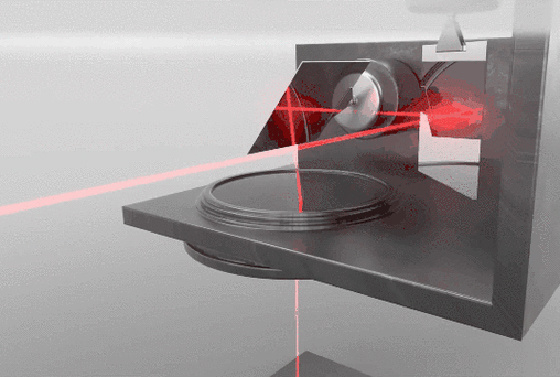

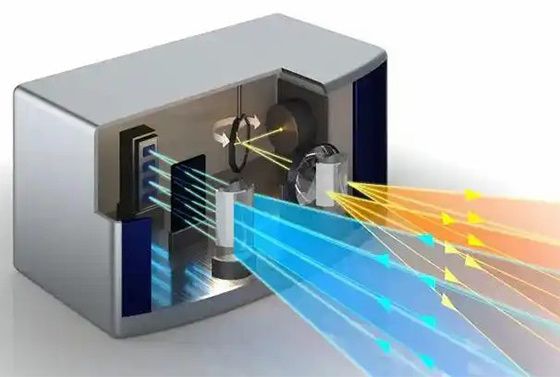

I. Overview of laser galvanometer technology

Laser galvanometer is a device that utilizes a laser beam for precise control, and realizes efficient and high-precision processing operations by rapidly reflecting the laser light. Laser vibration mirrors are characterized by high precision, high speed and high stability, and are widely used in a variety of material processing fields.

Second, the introduction of 3D printing technology

3D printing is a technology for manufacturing three-dimensional entities by stacking materials layer by layer. This technology can print complex geometric shapes and internal structures, and has a wide range of application prospects.

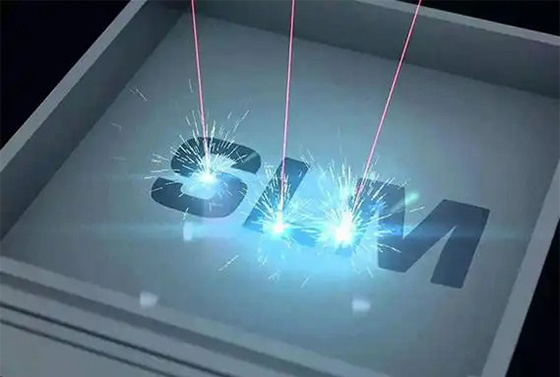

Third, the application of laser vibrator in 3D printing

1. Improvement of printing accuracy: laser vibrators can achieve sub-micron positioning accuracy, making the accuracy of 3D printing significantly improved. In the manufacture of fine parts and structures, the application of laser scanners is particularly important.

2. Enhance the fusion of materials: in the process of 3D printing, the laser scanner can accurately control the energy and position of the laser beam, to promote the fusion of the printed material, improve the overall quality of the printed object.

3. Increase printing speed: The high-speed reflected laser beam of the laser galvanometer enables the print head to move quickly, thus increasing the speed of 3D printing. This is important for mass production and commercial applications.

4. Multi-material printing: The laser galvanometer can precisely control the printing process of different materials and realize multi-material printing at the same time. This helps to create 3D entities with complex material requirements.

5. Heat Source Replacement: In some 3D printing processes, laser galvanometer can be used as a heat source to replace the traditional heating method, providing precise energy for material melting or sintering.

IV. Advantages and Challenges

The advantages of laser galvanometer in 3D printing include high precision, high speed, and flexible material selection. However, its application also faces some challenges, such as higher cost, higher skill requirements for operators, and higher equipment maintenance costs.

Related News