Application of vibrating mirrors in laser welding

2024-12-19

Application of vibrating mirrors in laser welding

I. Introduction

Laser welding, as an efficient and precise welding method, has been widely used in many industries. In this process, the galvanometer plays a vital role. The main function of the galvanometer is to guide and focus the laser, so that it accurately acts on the welding site to ensure welding quality and efficiency.

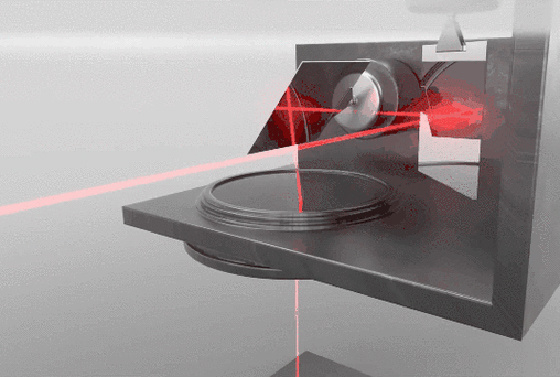

Second, the basic principle of galvanometer

Vibrating mirror is mainly composed of optical lens, motor and control system. Through the control system to drive the motor, so that the lens produces a small vibration, so as to realize the precise control of the laser beam. This precise control allows the laser to focus accurately on the welding site, to achieve high-quality welding.

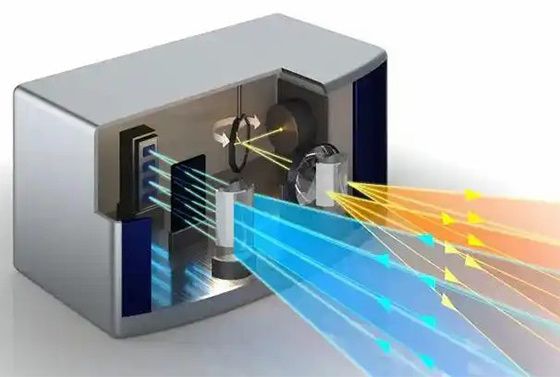

Third, the application of vibrating mirror in laser welding

1. Laser guidance: vibrating mirror can accurately control the direction and position of the laser beam, so that it is accurately aligned with the welding site. This ensures the effective utilization of laser energy and improves welding efficiency.

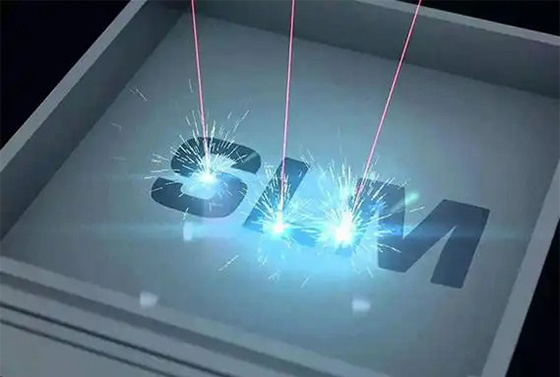

2. Improved welding quality: By precisely controlling the laser beam, the vibrating microscope is able to achieve high-precision welding and reduce welding defects, such as porosity, cracks, etc., thus improving welding quality.

3. Increased automation: the combination of vibrating mirrors and advanced control system can realize highly automated laser welding, reducing the cost and error of manual operation.

4. Applicable to a wide range of materials: the precise control of the vibrating microscope makes the laser welding applicable to a wide range of materials, including metals, plastics, etc., which broadens the application range of laser welding.

5. real-time monitoring and adjustment: vibrating mirror system usually has a real-time monitoring function, can real-time adjustment of the position and power of the laser beam to adapt to different welding needs.

Fourth, the advantages of galvanometer

1. high precision: vibrating mirror can realize high-precision laser control to ensure welding quality.

2. high efficiency: through automated control, improve welding efficiency.

3. Wide range of application: applicable to a variety of materials and different scales of welding.

4. Good stability: the galvanometer system has a high degree of stability, which can ensure stable work for a long time.

V. Conclusion

The galvanometer plays a central role in laser welding. Through precise control

Related News