Laser marking machine vibration mirror common faults and treatment way

2024-12-19

Laser marking machine vibration mirror common faults and processing methods

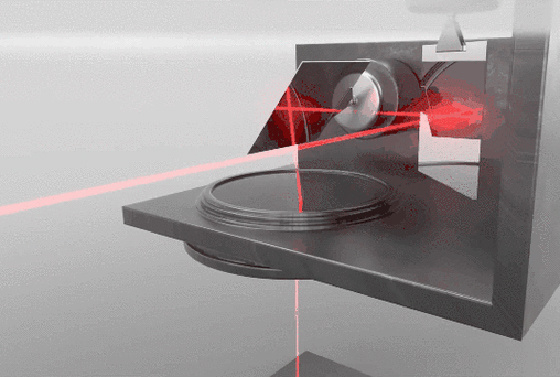

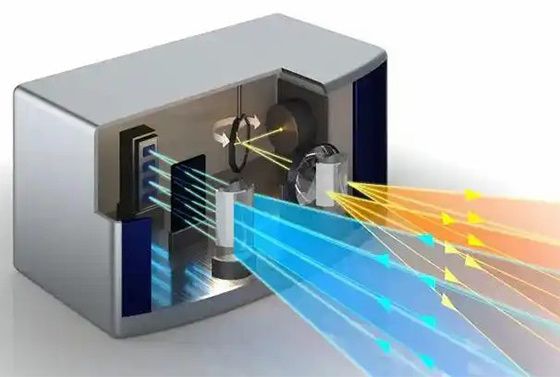

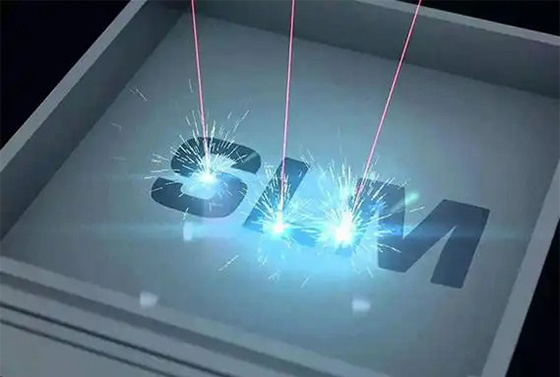

Laser marking machine is one of the indispensable equipments in modern production, which is widely used in marking, engraving and other processes of various materials. The vibrating mirror is an important part of the laser marking machine, responsible for controlling the scanning and positioning of the laser beam. However, in the process of use, the vibrating mirror may also have some failures, affecting the normal operation of the equipment. The following will introduce the common laser marking machine vibrating mirror failure and treatment.

I. Common Failures

1. unstable scanning speed: laser marking process, the scanning speed may change, affecting the marking effect.

2. Scanning lines are not clear: vibrator scanning lines may appear fuzzy, broken and so on. 3.

3. vibration mirror noise is too large: the use of the process, the vibration mirror may emit abnormal noise.

4. laser beam deviation from the predetermined position: the laser beam in the scanning process may deviate from the preset position.

Second, the way to deal with

1. unstable scanning speed: check whether the drive circuit of the vibrating mirror and the motor is running normally, adjust the control parameters to optimize the scanning speed. At the same time, ensure that the internal cooling system of the device is working properly to prevent performance degradation due to overheating.

2. Scanning lines are not clear: check whether the galvanometer lens is contaminated or damaged, if necessary, please clean or replace. In addition, adjust the laser marking machine focus and beam quality to ensure the stability of the laser beam.

3. vibration mirror noise is too large: check whether the vibration mirror internal mechanical components are loose or worn, if necessary, please tighten or replace. At the same time, ensure that the equipment is placed on a stable worktable to reduce vibration and noise.

4. Laser beam deviates from the intended position: Check the calibration status of the galvanometer and re-calibrate it to ensure the positioning accuracy of the laser beam. In addition, check whether the mechanical structure of the equipment is loose or deformed, and tighten or adjust it if necessary.

III. Preventive Measures

1. Check and maintain the equipment regularly to ensure that it is in good working condition.

2. Avoid using the equipment in harsh environments, such as high temperature, high humidity, and dusty environments.

3. follow the correct operating procedures to avoid damage to the equipment due to misuse.

4. use high quality consumables and accessories to ensure the performance and service life of the equipment.

Related News