Scanning galvanometer for 3D laser welding applications

2024-12-19

Scanning galvanometer in the application of three-dimensional laser welding

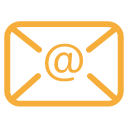

First, the basic principle of scanning galvanometer

Scanning galvanometer is a kind of precision optical device, its working principle is mainly through high-speed vibration reflection laser, realize the accurate scanning of the surface of the welding material. In three-dimensional laser welding, scanning galvanometer plays a vital role.

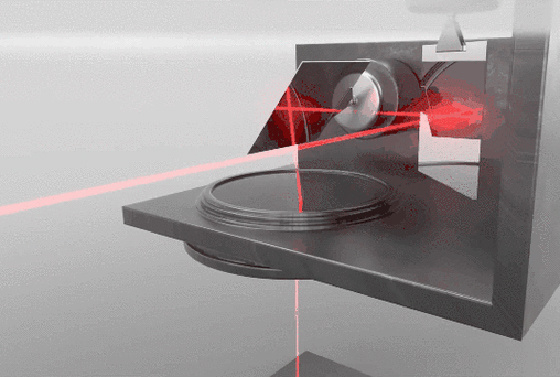

Second, three-dimensional laser welding on the demand for scanning galvanometer

In the three-dimensional laser welding process, due to the complexity of the three-dimensional shape of the workpiece, the scanning galvanometer needs to have high precision, high speed, high stability performance. In addition, for the depth of scanning and fine welding needs, also put forward higher requirements for the performance of the scanning galvanometer.

Third, the application of scanning galvanometer in three-dimensional laser welding

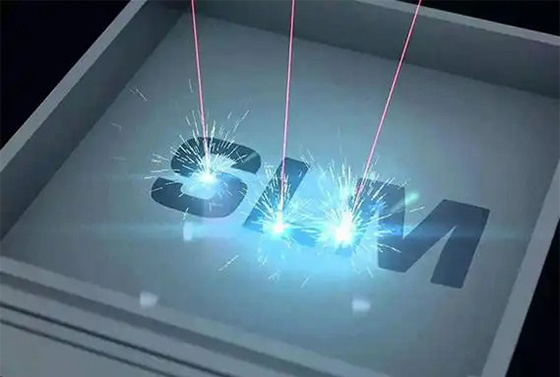

1. accurate positioning: scanning galvanometer can realize the precise control of the laser, so that the laser can accurately irradiate each part of the workpiece, to ensure the accuracy and integrity of welding.

2. High-efficiency welding: Through the high-speed vibration of the scanning galvanometer, the efficiency of laser welding can be greatly improved, reducing the welding time and improving productivity.

3. Complex shape welding: Scanning galvanometer can be adapted to the welding needs of various complex shape workpieces, and automated welding can be realized through programming control.

4. Heat-affected zone control: scanning galvanometer can accurately control the laser irradiation time and position, so as to accurately control the heat-affected zone and reduce welding deformation and residual stress.

Fourth, the technical advantages and application prospects

The application of scanning galvanometer in three-dimensional laser welding makes the laser welding technology more mature and advanced. Its technical advantage lies in the performance of high precision, high speed and high stability, as well as the appropriate

Related News