How does flying laser marking differ from static laser marking?

2024-12-19

Flying laser marking and static laser marking are two different process methods, which are significantly different in terms of application, working principle and characteristics. Here we will discuss in detail the differences between these two laser marking methods.

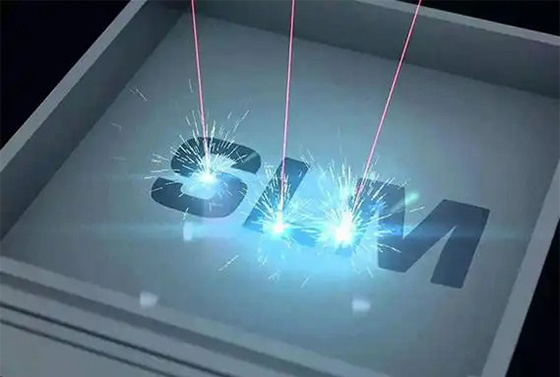

First, flying laser marking

Flying laser marking, also known as dynamic laser marking, is a high-speed, high-precision marking method. In this way, the laser beam moves at high speed to mark the surface of the workpiece, suitable for continuous production line material marking, such as metal, plastic and so on. The main feature of this method is high efficiency and the ability to quickly complete a large number of marking jobs. In addition, flying laser marking can also realize the marking of complex patterns and characters, and is suitable for workpieces of various shapes and sizes. However, it has higher requirements for operation precision, and needs precise control system and stable working environment.

Second, static laser marking

Static laser marking, also known as fixed laser marking, is a relatively slow but more accurate marking method. In this way, the workpiece is placed in a fixed position, and the laser beam is positioned and focused on the surface of the workpiece for marking through the high-precision optical system. This method is suitable for occasions that require high accuracy, such as jewelry, watches and other precision manufacturing. The advantage of static laser marking is its high precision, which can ensure the quality and consistency of each mark. In addition, it can also realize deep marking of various materials, including some materials with poor laser absorption. However, the efficiency of static laser marking is relatively low, and it is suitable for marking tasks with small batch or high precision requirements.

Comparison

There are obvious differences between flying laser marking and static laser marking in terms of application scenarios, efficiency and precision. Flying laser marking is suitable for high-speed, high-volume production, while static laser marking is suitable for high-precision, small batch production. In addition, flying laser marking requires high operational precision, professional operators and advanced control systems; while static laser marking is relatively simple and requires low operator skills.

In general, flying laser marking and static laser marking have their own advantages and applicable scenarios. Which one to choose depends on the specific production needs and conditions. In the future, with the progress of science and technology, these two process methods may be further developed to bring us more convenience and possibilities.

Translated with DeepL.com (free version)

Related News