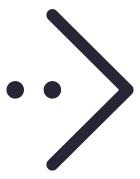

Fly-Ⅲ Scanning Galvanometer series

The Fly-Ⅲ series is a new generation of high-performance laser mirrors designed to meet the demands of industrial laser processing at higher speeds and with greater accuracy. With advanced technical design and excellent performance, it is the perfect choice for a wide range of processing applications.

Category:

Key words:

Scanning Galvanometer series

Product details

Parameter Table

| Product Series | Fly-Ⅲ | Fly-Ⅲ | ||

| Incoming Aperture |

20mm |

30mm |

||

| Wavelength Options |

355nm/532nm/1030nm-1080nm /9.4um-10.6 um |

355nm/532nm/1030nm-1080nm /9.4um-10.6 um |

||

| Maximum Scanning Angle |

20Rad. |

20Rad. | ||

| Response Time |

110us |

110us |

||

| Step Response Time | 1% Full Angle |

0.49us |

0.85us | |

| 10% Full Angle |

2.4 us |

4.0us | ||

| Typical Scanning Speed | Marking Speed |

1.2 m/s |

0.8m/s |

|

| Positioning Speed |

6.0m/s |

3.0m/s | ||

| Character processing speed |

Good Quality[cps] |

310 |

210 |

|

|

200 |

120 | |||

| Long Time Drift (30 minutes warm-up) |

Zero-point Drift |

<150urad |

<150urad |

|

| Incremental Drift |

<120ppm |

<120ppm |

||

| Temperature Drift | Zero-point Drift |

<30urad/℃ |

<30urad/℃ | |

| Incremental Drift |

<30ppm/℃ |

<30ppm/℃ |

||

| Repeatability |

<2 |

<2 | ||

| Resolution |

12urad |

12urad |

||

| Nonlinearity |

<0.5 |

<0.5 | ||

| Power Supply |

±15V DC, ≥5A |

±15V DC, 25A |

||

| Communication Protocols |

XY2-100 |

XY2-100 | ||

| Operating Temperature (°C) |

25±10°℃ |

25±10℃ |

||

| Weights |

6.68 Kg |

6.68Kg | ||

| Package Weight |

18.98kg |

18.98kg |

||

| Outer Width Dimensions In mm |

179×139×197 |

197×109×180 | ||

|

Lens withstand power:Fiber Optics |

Standard ≤4000W Customizable≤6000W |

Lens withstand power:Fiber Optics |

Optical fiber≤4000W Optical fiber≤6000W |

|

|

Lens withstand power: CO2 |

Standard ≤50W Higher power can be customized |

(3)Long-term drift(8h drift after 30min warm up) |

|

|

|

Conventional cooling method |

Standard Equipment |

typical air requirements |

20L/min@Yuqiang <2 bar |

|

|

Water cooling method |

Customizable 5L/min @Pressure <4 bar |

Typical water requirements |

5L/min@Yuqiang |

|

Product Features

• High-speed marking: support faster marking speed and filling efficiency, marking speed up to 5000mm/s, positioning speed up to 1600mm/s, significantly improve processing efficiency.

• Uniform filling: XY axis matching degree optimisation, to ensure that the filling line is uniform and smooth, the processing effect is more exquisite.

• High Precision Stability: Adopting imported core components, the temperature drift is less than 25µrad/°C during long time working, the precision is kept excellent to ensure the consistency of each machining.

• Low Response Time: Optimised motor and control design, the response time is only 110µs, significantly reducing the delay.

• Superior thermal performance: optimised structural design, stable and reliable operation, adaptable to a variety of complex working environments.

Product Drawings

Applicable Scenes

• Suitable for laser engraving, metal marking, PCB circuit board processing and other high-precision laser application scenarios. Especially in the industrial production which requires high processing efficiency and stability, the performance is outstanding.

• With excellent performance, high reliability and wide compatibility, FETEN III scanning galvanometer has become a high-quality solution for the laser industry, suitable for all kinds of scenarios from R&D to mass production.

Custom design OEM solutions

We support standard and custom products and can provide customized services on the basis of standard products

Our experienced R&D team will support technical issues

It is our pleasure to provide you with OEM services

Quality Control

Our technicians and QC team test the original products one by one and strictly comply with the ISO9001 quality management system and ISO9001 Environmental management system standard operating requirements.

We will test the goods strictly according to our standard inspection before shipment

Product Delivery

Timely Delivery: We promise to deliver products on time to ensure that your production plans are not disrupted.

Real-time Tracking: Provide real-time logistics information so that you can always know the location of your goods.

Professional Packaging: Provide professional packaging for different products to ensure safety during transportation.

Flexible Delivery Options: Provide multiple delivery options based on customer needs to flexibly respond to different scenarios.

Quality After-sales Service: Our team will be available to provide support and solve any problems encountered during the delivery process.

Core Advantages

Service

Prompt response within 12 hours

Support OEM

Short delivery time

A strong R&D team supports perfect custom projects

Ability

More than 19 years of experience in SMT peripheral equipment development and manufacturing industry

Stable supply chain

Perfect quality control system

Complete SMT peripheral solutions

Fabulous after-sale service

Plant Environment

Our Partner

CORPORATE ATLAS