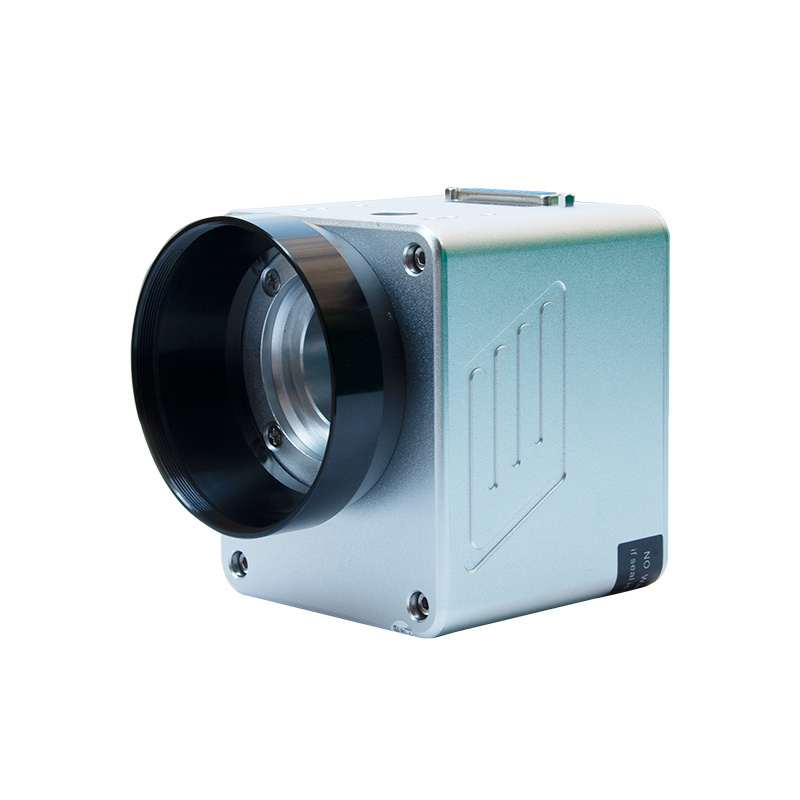

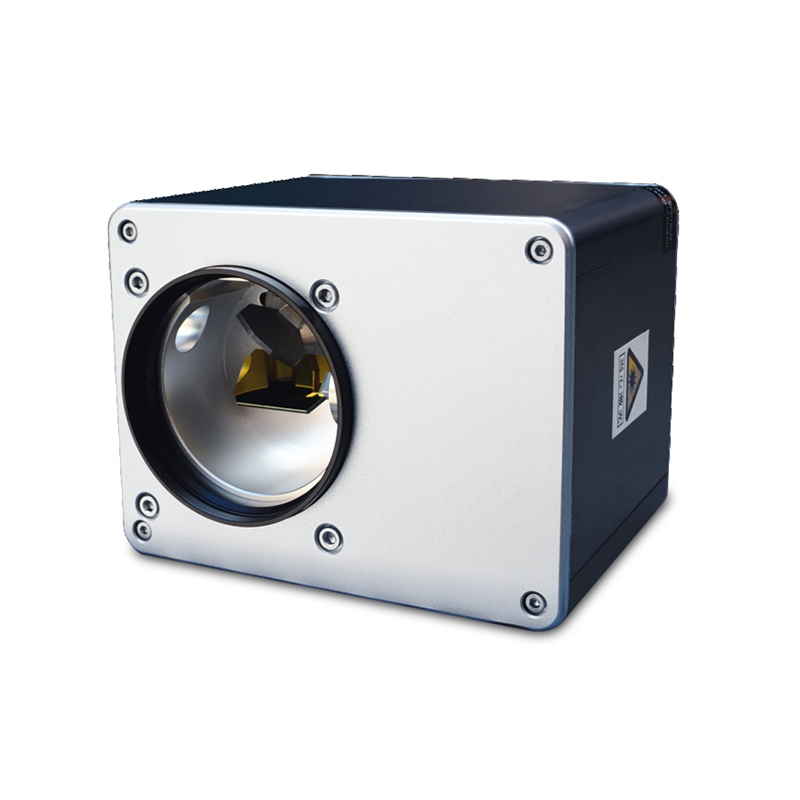

Fly-I Scanning Galvanometer series

The First Generation Scanner (Fly-I Series) scanner is a high-performance laser scanning head designed for high-speed, high-precision industrial laser applications and is widely used in marking, engraving, cutting and drilling scenarios. Its excellent performance and reliability can meet a variety of industrial processing needs.

Category:

Key words:

Scanning Galvanometer series

Product details

Parameter Table

| Product Series |

Fly-I |

|

| Incoming Aperture |

10mm |

|

| Wavelength Options |

355nm/532nm/1030nm-1080nm/9.4μm-10.6 μm |

|

| Maximum Scanning Angle |

±0.35Rad. |

|

| Response Time |

160us |

|

| Step Response Time | 1% Full Angle |

350us |

| 10% Full Angle |

750us |

|

| Typical Scanning Speed | Marking Speed |

2.5m/s |

| Positioning Speed |

10m/s |

|

| Character processing speed |

Good Quality[cps] |

730 |

|

High Quality[cps] |

590 |

|

| Long Time Drift (30 minutes warm-up) |

Zero-point Drift |

<150urad |

| Incremental Drift |

<250ppm |

|

| Temperature Drift | Zero-point Drift |

<50urad/℃ |

| Incremental Drift |

<150ppm/℃ |

|

| Repeatability |

2urad |

|

| Resolution |

16bit |

|

| Nonlinearity |

<1mrad/44° |

|

| Power Supply |

±15V DC, Max. 3A |

|

| Communication Protocols |

XY2-100 |

|

| Operating Temperature (°C) |

25±10℃ |

|

| Weights |

1.48kg |

|

| Package Weight |

2.26kg |

|

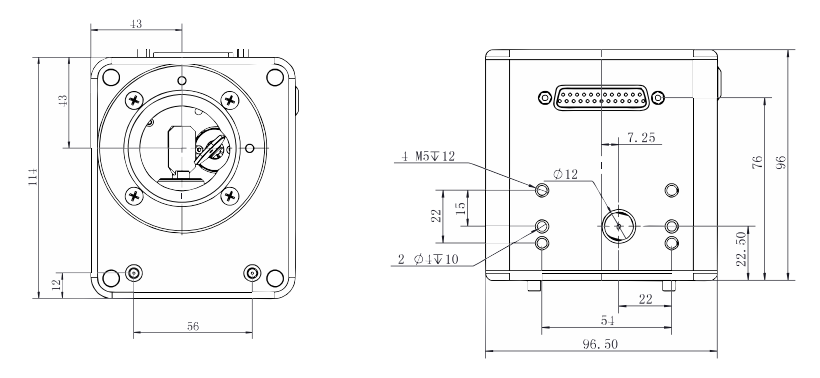

| Outer Width Dimensions In mm |

96×96.05×114 |

|

Product Features

• High-speed performance: marking speed up to 2500mm/s to meet the demand for rapid processing.

• Small temperature drift: maintain stable processing accuracy in long time working.

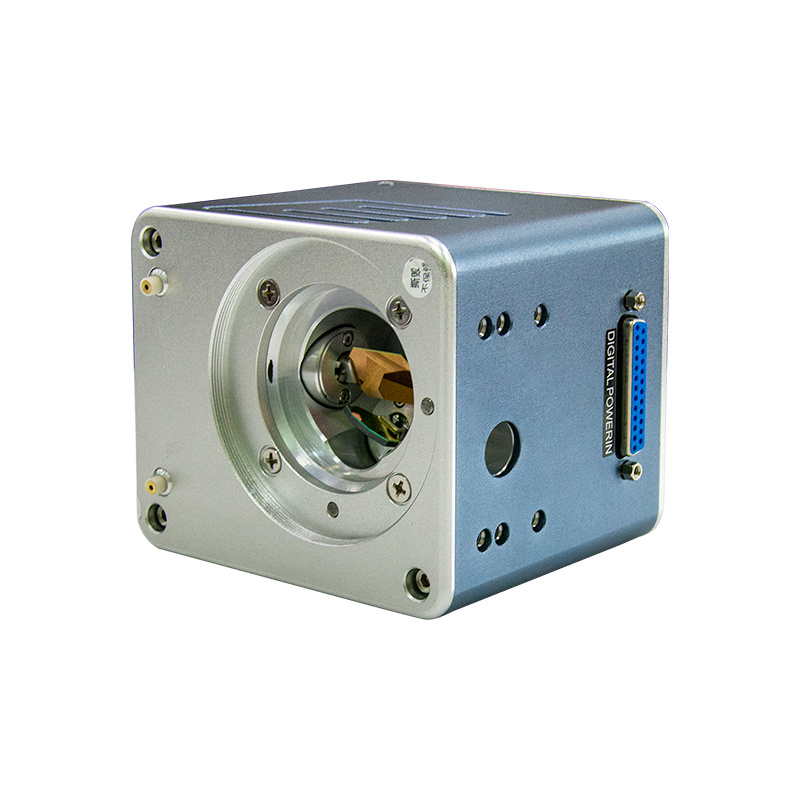

• Digital communication: using XY2-100 standard protocol, support digital command control, interface DB25, strong compatibility

• Accurate positioning: optional double red light positioning with calibration function, making the operation more efficient and convenient.

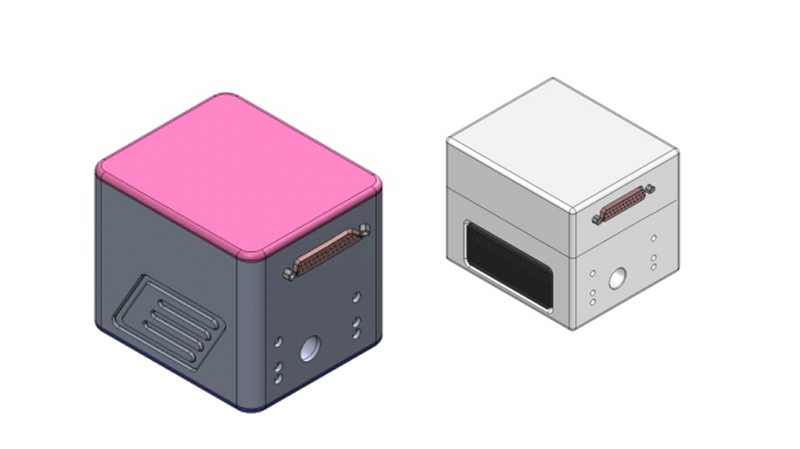

• Stable and durable: full metal shell design, with good anti-vibration and dustproof ability.

Product Drawings

Applicable Scenes

• laser marking: precision marking of metal, plastic, glass and other multi-materials.

• laser cutting: efficient cutting processing of thin materials.

• Laser engraving: fine engraving of complex patterns and text.

• Other applications: laser drilling and other industrial processing scenarios.

Choose our oscillators to help your laser processing system achieve a more efficient and precise processing experience!

Custom design OEM solutions

We support standard and custom products and can provide customized services on the basis of standard products

Our experienced R&D team will support technical issues

It is our pleasure to provide you with OEM services

Quality Control

Our technicians and QC team test the original products one by one and strictly comply with the ISO9001 quality management system and ISO9001 Environmental management system standard operating requirements.

We will test the goods strictly according to our standard inspection before shipment

Product Delivery

Timely Delivery: We promise to deliver products on time to ensure that your production plans are not disrupted.

Real-time Tracking: Provide real-time logistics information so that you can always know the location of your goods.

Professional Packaging: Provide professional packaging for different products to ensure safety during transportation.

Flexible Delivery Options: Provide multiple delivery options based on customer needs to flexibly respond to different scenarios.

Quality After-sales Service: Our team will be available to provide support and solve any problems encountered during the delivery process.

Core Advantages

Service

Prompt response within 12 hours

Support OEM

Short delivery time

A strong R&D team supports perfect custom projects

Ability

More than 19 years of experience in SMT peripheral equipment development and manufacturing industry

Stable supply chain

Perfect quality control system

Complete SMT peripheral solutions

Fabulous after-sale service

Plant Environment

Our Partner

CORPORATE ATLAS